RAW MATERIALS’ QUALITY CONTROL

Each batch of raw materials passes three checks!

1. During acceptance at the factory.

2. After cleaning.

3. Before charging the furnace.

CONTROL

FeTi GRADES

We are ready to implement your specific requirements for the content of gases and chemical elements.

0-2 мм / 0-5 мм / 5-50 мм / 20-100 мм / 50-200 мм

Minimum values: Al - 0,3% V - 0,3% С - 0,1% N - 0,15% O - 1%

We are ready to implement your specific requirements for the content of gases and chemical elements.

0-2 мм / 0-5 мм / 5-50 мм / 20-100 мм / 50-200 мм

Minimum values: Al - 0,3% V - 0,3% С - 0,1% N - 0,15% O - 1%

Should you have any specific requirements as to the gas content of the finished product,

we will manufacture ferrotitanium products exactly to your order.

0-2 мм / 0-5 мм / 5-50 мм / 20-100 мм / 50-200 мм

Minimum values: Al - 0,3% V - 0,3% С - 0,1% N - 0,15% O - 1%

LUMP FeTi

An individual size is possible according to customer's specification

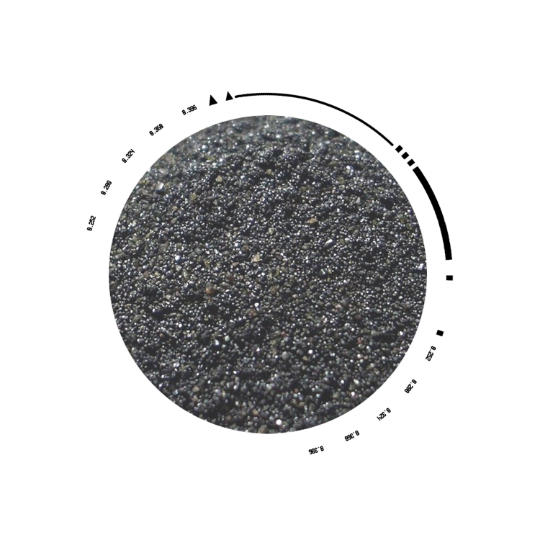

POWDERED FeTi

Size 0-2 mm

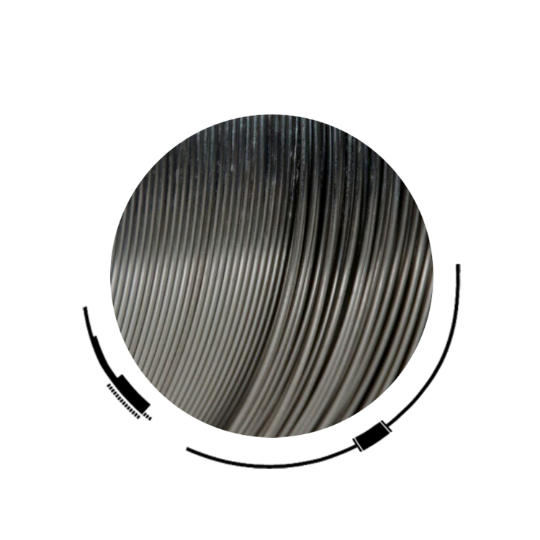

FeTi CORED WIRE

Diameter from 14 mm according to customer's specification

DO YOU NEED A TAILOR-MADE FERROTITANIUM GRADE?

WE WILL MAKE IT!

Please specify the required ferrotitanium characteristics in the comment to your application.

WE WILL MAKE IT!

Please specify the required ferrotitanium characteristics in the comment to your application.

DO YOU NEED A CUSTOM FERROTITANIUM GRADE? WE WILL MAKE IT!

• Unique raw material cleaning technology

• Laboratory control of the composition after cleaning

• Fraction size evaluation

• Melting program development

• Induction furnaces with the capacity of 1-6 tons

• Charge according to the melting program

• Melting parameters control (temperature, humidity, gas content)

• Laboratory control of finished ferrotitanium product chemical composition

• Crushing and screening according to standards or the customer’s specification

• Sorting

• Conformity control

• Party labeling

• Storage in dry and warm warehouses with temperature and humidity control

• Packaging in big bags before delivery to the customer

• Marker-based batch shipment control

• Delivery by proprietary motor vehicles

• Unique raw material cleaning technology

• Laboratory control of the composition after cleaning

• Fraction size evaluation

• Melting program development

• Induction furnaces with the capacity of 1-6 tons

• Charge according to the melting program

• Melting parameters control (temperature, humidity, gas content)

• Laboratory control of finished ferrotitanium product chemical composition

• Crushing and screening according to standards or the customer’s specification

• Sorting

• Conformity control

• Party labeling

• Storage in dry and warm warehouses with temperature and humidity control

• Packaging in big bags before delivery to the customer

• Marker-based batch shipment control

• Delivery by proprietary motor vehicles

Each batch of raw materials passes three checks!

1. During acceptance at the factory.

2. After cleaning.

3. Before charging the furnace.

Finished products pass three checks!

1. By internal laboratory after each melt.

2. By an independent laboratory after batch picking.

3. By the customer’s laboratory during acceptance by the customer.

Each batch of raw materials passes three checks!

1. During acceptance at the factory.

2. After cleaning.

3. Before charging the furnace.

Finished products pass three checks!

1. By internal laboratory after each melt.

2. By an independent laboratory after batch picking.

3. By the customer’s laboratory during acceptance by the customer.